Why This Program

Step into a welding career with hands-on, interactive learning using cutting-edge industry tools at Northampton Community College. This welding program is flexible to your schedule: you can study full-time or part-time in daytime or evening courses, and you can choose to pursue a Welding Fundamentals Specialized Diploma, Welding and Fabrication Certificate, or Associate in Applied Science degree in Welding Technology. Our Bethlehem, PA–based welding programs prepare you for certifications from the American Welding Society (AWS), including the AWS SENSE certification.

Program Details

Semesters: 4

Credits: 68

College Catalog: View Curriculum

Program Map: Download PDF

Locations: BethlehemProgram Overview:

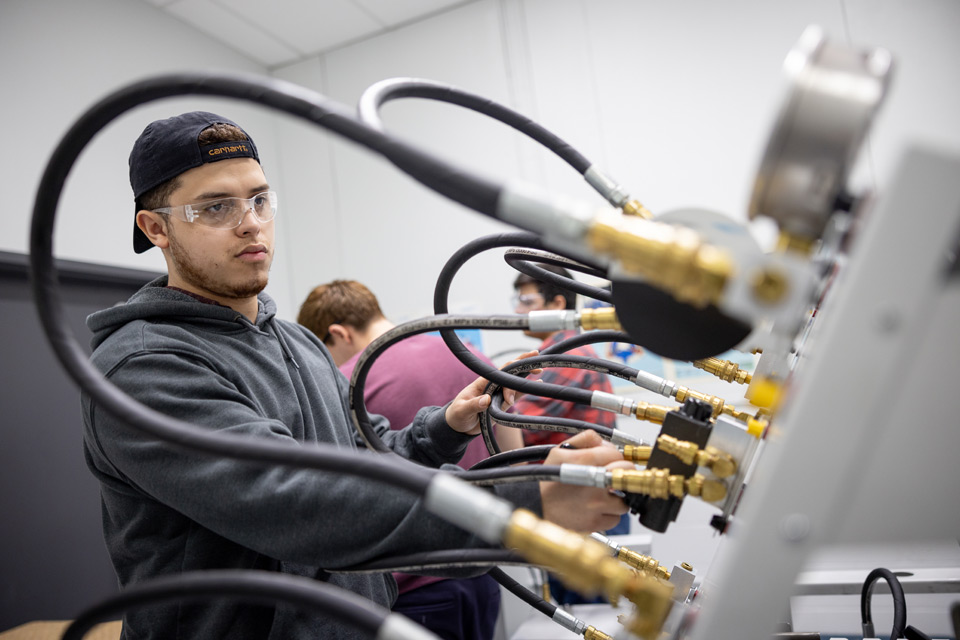

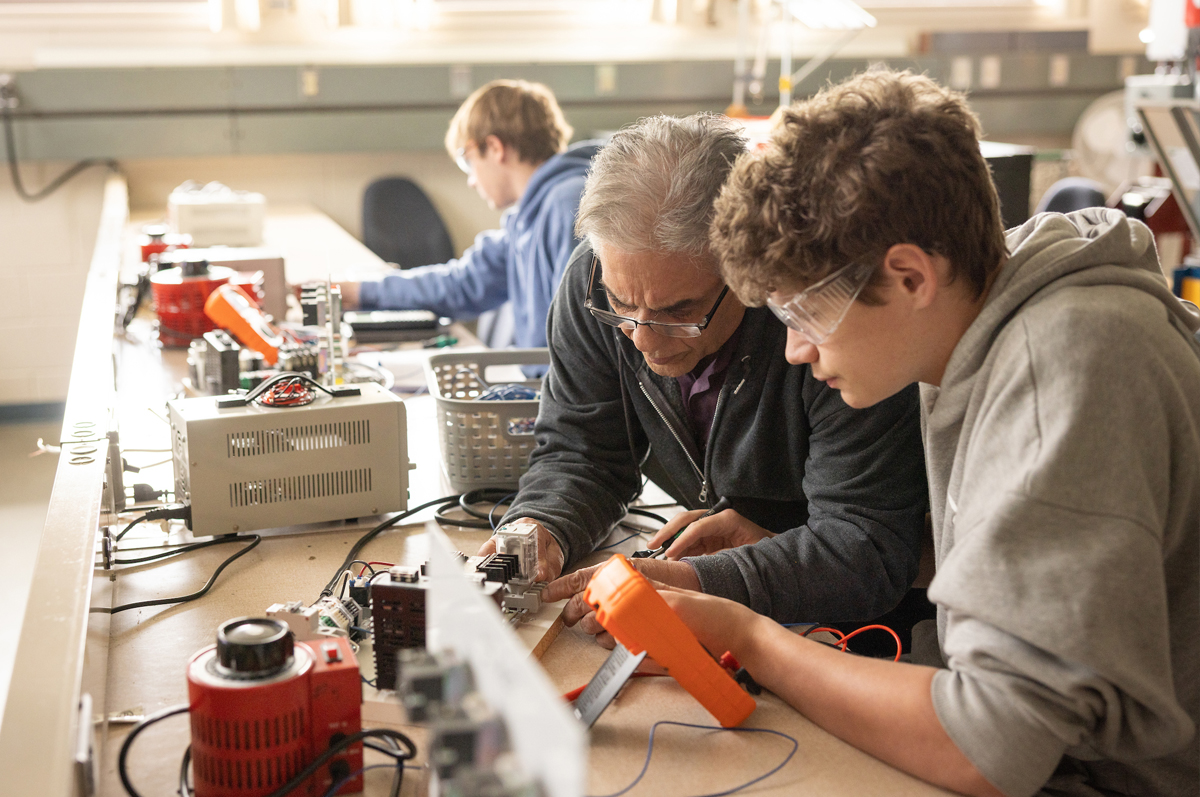

Gain marketable skills from experience using state-of-the-art welding equipment and interpreting blueprints to practice as a team player, critical thinker, and decision-maker in the highly technical welding trade. With a welding associate degree, you’ll develop professional attitudes, values, and ethics in preparation for your career or to transfer to a four-year bachelor’s degree program.

Semesters: 3

Credits: 50

College Catalog: View Curriculum

Program Map: Download PDF

Locations: BethlehemProgram Overview:

Whether you’re starting out as a welder, changing careers, or looking to update your skills and certification, the welding and fabrication certificate program will equip you with hands-on practice and techniques to excel in the welding trade. Our state-of-the-art welding facilities and coursework are designed to prepare you for American Welding Society certification. Your credits from the certificate can also be applied to our welding technology A.A.S. degree, which you may choose to pursue after gaining further professional experience.

Semesters: 2

Credits: 27

College Catalog: View Curriculum

Program Map: Download PDF

Locations: BethlehemProgram Overview:

Advance your existing welding skills or fast-track into a welding profession with NCC’s specialized diploma in welding fundamentals. You’ll learn pipe welding, advanced plate welding, OSHA standards, and gas tungsten arc & semiautomatic welding processes, plus essential abilities in professional teamwork and maintaining high quality standards. With the specialized diploma, you can take an entry-level welding job or continue your education by applying your credits to NCC’s certificate and A.A.S. welding programs.

Program Information

As a graduate from one of NCC’s welding programs in PA, you will be able to:

- Demonstrate the proper use of Gas Metal Arc Welding (GMAW) in short circuit and spray transfer mode, Flux Cored Arc Welding (FCAW), and Submerged Arc Welding (SAW) equipment

- Produce flat position padding and horizontal position tee joint fillet type welds with the GMAW, FCAW, and SAW processes that consistently meet the requirements of the American Welding Society

- Identify common GMAW, FCAW, and SAW discontinuities, and explain what causes their occurrence and how they negatively impact the weld

- Demonstrate the proper use of Gas Tungsten Arc Welding (GTAW) and Plasma Arc Cutting (PAC) equipment

- Identify common GTAW discontinuities and explain what causes their occurrence and how they negatively impact the quality of the weld

- Produce flat position padding with Torch Brazing (TB)

Our location in Bethlehem, PA is at the heart of Pennsylvania’s industrial strip, making NCC an ideal place to launch your welding career. Here, 90% of your learning will be hands-on in our leading-edge Hartzell Advanced Technology Hall and through our extensive network of area employers.

As a welding professional, you’ll need academic and technical competence in fabricating and reading blueprints, industrial heat treating, metallurgy, and safety protocols. At NCC, you’ll develop your troubleshooting skills, theoretical knowledge, and on-the-ground expertise to stand out in this high-demand industry. Our campus resources, like Career Services, can connect you with competitive welding opportunities locally and around the state. NCC’s welding associate degree also prepares you to pursue further study at a four-year institution.

If you’re seeking an affordable welding program in Pennsylvania, consider the holistic benefits of NCC’s education model: you’ll gain hands-on experience, technical and theory expertise, and professional skills that contribute to your long-term career success, all at a competitive cost.

And you'll have another advantage: access to scholarships and financial aid. NCC gives out more than $46 million in scholarships each year, including awards that support welding students like the Mattoli Foundation Annual Scholarship and the Orbel Corporation Scholarship Endowment. Learn more about NCC tuition.